Share this post

Just as with traditional farming, water is the primary component required for vertical farms to thrive. Water hygiene in vertical farming is crucial, as it can affect crop health and nutrient delivery. Many growers make the mistake of simply adding nutrients to their water supply and assuming that would be enough for a healthy yield.

However, there are many components to consider, and without the proper products and maintenance, you could face problems such as algae, biofilms, and pest infestations. To minimize these risks, we’ve provided a short guide to help you optimize water quality so you can have a successful yield year-round.

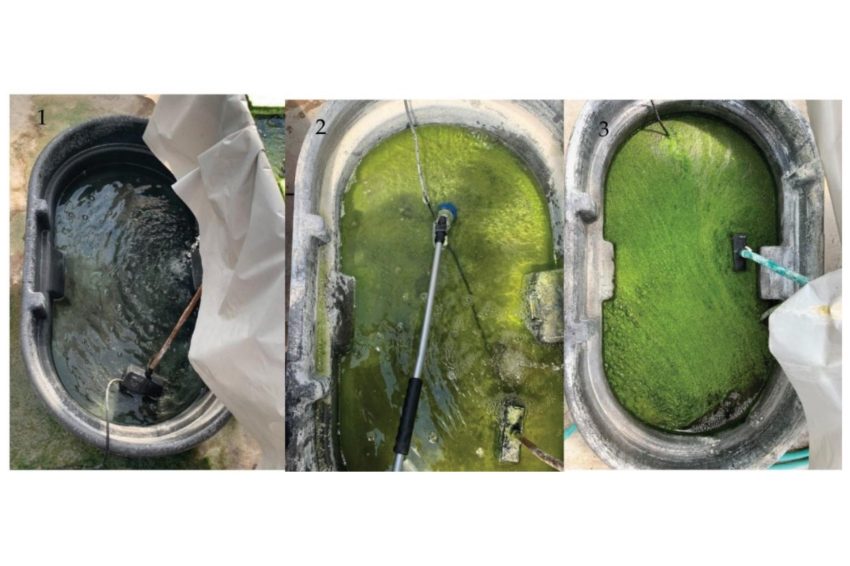

(Featured image credit: https://www.mdpi.com/2311-7524/8/7/569)

What is In Vertical Farming Water?

Indoor vertical farms or hydroponic systems need water to provide hydration and nutrients directly to the roots of crops. However, there may be certain components in the water that might not be suitable for hydroponic vertical farms. For example, municipal water may be too saline, and it can contain chloride. You won’t know what’s inside your water unless you get it tested.

Growers sometimes send samples of water to labs or universities so they can get a full breakdown of what’s inside their water. Testing can reveal imbalances in raw water and re-circulated water so growers can make adjustments when cultivating crops.

What Type of Water is Ideal for Vertical Farming?

There are various types of water resources that you can use for vertical farming operations, such as the following

- Well water: It can be used for hydroponic vertical farming, but it will need treatment because it may contain high mineral content, heavy metals, and potential pathogens.

- Rainwater: Some growers use barrels or tanks to catch rainwater for their farming. Rainwater is free and abundant in places where there’s plenty of rainfall. It’s also ideal if the area experiences frequent droughts or water shortages. Rainwater harvesting is a great sustainable option for small-scale vertical farming.

- Municipal water: This is the most commonly used type of water for vertical farming, as it’s readily available. However, it may need to be filtered first as this type of water can be hard and acidic. Typical filtration methods include reverse osmosis or UV sterilization.

The best type of water to use for any indoor vertical farm is reverse osmosis, as it prevents contaminants from municipal water from killing off your crops. Furthermore, one of the benefits of vertical farming is that it uses 98% less water than traditional farms, so growers can create sustainable farming practices.

Why Water Hygiene is Critical in Vertical Farming Systems

If the water in vertical agriculture is dirty, it can hinder the crop’s ability to absorb vital elements. For example, algae can reduce oxygen in the water. Additionally, biofilm deposits can block irrigation systems, which can reduce water flow. This can increase operational costs as biofilms can degrade drip irrigation systems.

Proper water hygiene in vertical farming ensures food safety when growing crops and prevents breakdowns. Furthermore, clean water serves as a carrier for important nutrients that crops need in order to grow. The quality of your water will determine the presence of these nutrients and their availability to your crops. Proper water management is needed to prevent diseases in hydroponic systems.

Signs Water Quality in Vertical Farming is Low

In hydroponics, there are several signs that your water quality is not up to standard. Unclean water can have a significant environmental impact, like foodborne illnesses. Crop production will fail if you don’t prevent the following water issues:

- Greenwater: Algae is common in hydroponics. It’s a green slime that develops inside tanks or stagnant water. It’s a plant-like organism that competes for nutrients and oxygen in water. If you notice a green slimy coating on surfaces, you may have a greenwater problem.

- Foul odors: Another telltale sign your water quality is low is if you have a foul smell coming from tanks. This is often a sign of bacterial contamination or even root rot. Decaying organic matter can also cause water to smell bad. This is why cleaning a hydroponic system is important.

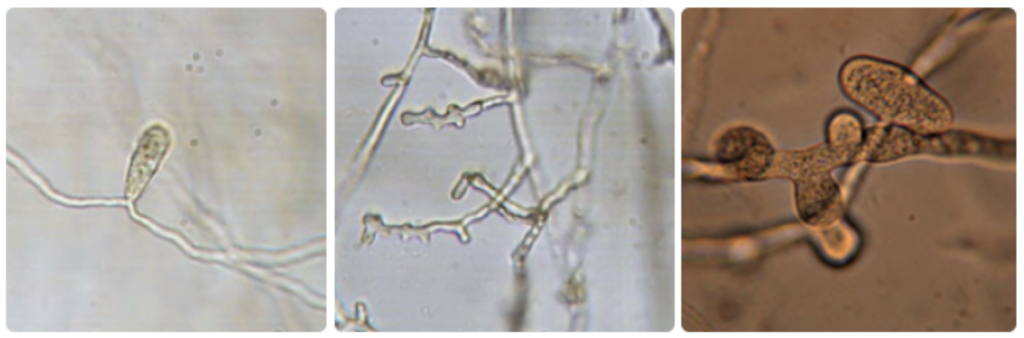

- Pathogens: There are specific waterborne diseases that can develop in hydroponics, like Pythium (which resembles fungi) and Phytophthora (which causes root or foliar blight). These pathogens can dwindle food production quickly, as they attack roots.

- Fungal diseases: Vertical farming, which utilizes nutrient-rich water, is more susceptible to fungal diseases. One of the most common fungal diseases is Fusarium. It attacks the vascular system of crops and blocks the intake of nutrients and water.

Growers must learn how often to change the water in their vertical farm and the right products for cleaning to prevent these issues.

What Affects Water Quality in Vertical Farming?

When growing crops in a controlled environment, there are certain factors that can affect the quality of the water. Whether you’re growing leafy greens, herbs, or vegetables indoors, you must monitor the following.

High Temperatures

Many new growers don’t consider the temperature of their nutrient solutions, which can be extremely detrimental to plant health. If temperatures in controlled indoor farms are too low, it can shock the crops, and they will die. But if the temperatures are too high in the water, it will be more prone to developing algae and bacteria.

To balance temperature and for efficient water methods, growers use air stones or chillers, ideal for aquaponics and hydroponics.

Imbalanced pH Levels

Another problem that growers face is pH imbalances in their vertical hydroponic farms. pH measures the acidity in hydroponics, and it must be at a specific level for the safety of your crops. If your pH level is less than 7, it’s too acidic, and if it’s higher than 7, it’s considered basic. For soilless culture, the pH levels should be 6 to 6.5.

What’s more, if your pH levels are too low, it can prevent crops from absorbing nutrients like calcium and magnesium. However, if the pH in water treatment is too high, it can cause nutrient toxicity, and leaves may start to yellow and wilt.

Lack of Oxygen

Plant growth needs water and oxygen to survive. Stagnant water in vertical farms that don’t get enough oxygen can start to go green. Greenwater, fungi, and bacteria are all common problems associated with the lack of oxygen in vertical farming practices. Air pumps are typically used to prevent this issue.

Biofilm Buildup and Its Impact on System Performance

Biofilm forms when bacteria and other microbes stick to wet surfaces in vertical farming water systems and produce a slimy matrix that anchors them there. Nutrient-rich recirculating water and stagnant zones in pipes, drippers, and reservoirs promote rapid attachment and growth of these biofilms.

Furthermore, biofilm can:

- Restrict water flow as it causes clogs

- Create uneven nutrient delivery to roots, which reduces plant uptake efficiency and slows growth

- Shelters harmful pathogens and resists disinfection, which leads to poorer water quality, unstable pH, and low dissolved oxygen levels

- Increase maintenance needs and labor costs in hydroponic systems

How to Keep Vertical Farming Water Clean

Although there are problems that you may face with water maintenance in your vertical farm, there are methods to assist with keeping your systems clean. It’s important to note that maintaining of a vertical farm starts with a proper schedule to ensure the water and space for crops are attended to.

Then it comes down to using the right products to keep your water systems clean. There are two products that assist with maintaining vertical farm water usage: Clear Flow and Clear Zona. Both these products are eco-friendly, so they’re safe to use during production, which in turn reduces the time needed to clean or tear down a vertical farm.

Use Clear Zona or Clear Flow according to your needs. Clear Zona is ideal for problems with greenwater or decaying plant matter in hydroponic systems. To prevent irrigation blockages from Biofilms, use Clear Flow as it will remove the layers of biofilm and improve the flow of water lines and drippers.

Final Thoughts – Reduce Water Issues the Right Way

Clean water creates reliable vertical farming since it drives nutrient delivery, root health, and food safety. Poor water quality allows biofilm and green water to interfere with flow rates, oxygen levels, and system consistency, which increases downtime and risk across the farm.

Clear Flow supports system performance by removing biofilms. Plant-based enzymes and trace minerals break down buildup without harsh chemistry, so it’s suitable for recirculating systems. A shock treatment helps clear older systems, while routine dosing keeps biofilm from returning.

Clear Zona targets green water and stubborn organic matter. Its water-based formula uses catalytic enzymes and aerobic microbes for sludge and plant debris without chlorine, acid, or peroxide. Regular use helps reduce maintenance needs while keeping water clearer and more stable throughout all production stages.